The reliability and performance of bearings are paramount in the world of machinery. As components that facilitate smooth rotation and movement, bearings play a vital role in the overall efficiency of various industrial applications. While original equipment manufacturer (OEM) bearings are often associated with quality, aftermarket bearings have gained prominence as a viable and often superior alternative. This article explores the advantages of choosing aftermarket bearings from trusted manufacturers, highlighting the factors that make them a top choice in the industry.

The Evolution of Aftermarket Bearings

Traditionally, OEM bearings were the default choice for machinery components due to the perceived assurance of quality and compatibility. However, the landscape has evolved, and aftermarket bearings have risen to prominence, offering several compelling advantages.

The Reasons that Make Aftermarket Bearings A Best Choice

Cost-Effectiveness without Compromising Quality

One of the primary reasons many industries are turning to aftermarket bearings is cost-effectiveness. Aftermarket bearings are often more competitively priced than their OEM counterparts, allowing businesses to achieve significant cost savings without compromising on quality. This affordability is especially appealing for industries facing budget constraints or looking to optimize operational costs without sacrificing performance.

Technological Advancements and Innovation

Contrary to the misconception that aftermarket components are generic or inferior, many aftermarket bearing manufacturers invest heavily in research and development. This commitment to innovation results in technologically advanced bearings that can outperform OEM equivalents in certain aspects. Advanced materials, precision manufacturing techniques, and innovative designs contribute to the superior performance of aftermarket bearings.

Wide Range of Options and Availability

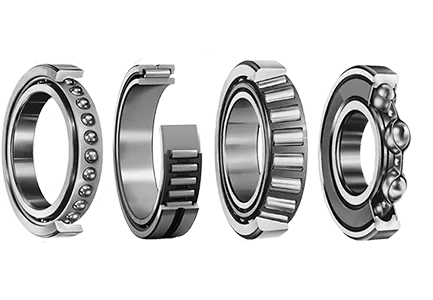

Aftermarket bearing manufacturers recognize the diverse needs of industries and offer a wide range of options to accommodate various applications. This extensive product range allows businesses to select bearings tailored to their specific requirements, ensuring optimal performance in different operating conditions. Moreover, the availability of aftermarket bearings from multiple suppliers enhances competition, fostering a market where manufacturers strive to outdo each other in terms of quality and features.

Key Advantages of Aftermarket Bearings

1. Quality Assurance and Certification

Contrary to common misconceptions, reputable aftermarket bearing manufacturers prioritize quality and reliability. Many aftermarket bearings undergo rigorous testing and adhere to international standards to ensure they meet or exceed industry requirements. Certifications such as ISO 9001 demonstrate a manufacturer's commitment to maintaining high-quality standards in their production processes.

2. Customization for Specific Applications

Aftermarket bearings are not one-size-fits-all solutions. Trusted manufacturers understand the importance of customization to suit specific applications. Whether it's the agricultural sector, automotive industry, or heavy machinery, aftermarket bearings can be tailored to meet the unique demands of different environments and operating conditions.

3. Compatibility with OEM Specifications

While aftermarket bearings offer room for innovation and improvement, reputable manufacturers ensure that their products remain compatible with OEM specifications. This compatibility is crucial for industries that require seamless replacements or upgrades without the need for extensive modifications to existing machinery.

4. Cost Savings and Value for Money

Cost considerations often drive decisions in the industrial sector, and aftermarket bearings provide a compelling value proposition. The cost savings realized by choosing aftermarket options can be reinvested in other areas of the business, contributing to overall operational efficiency.

5. Availability and Quick Turnaround

Aftermarket bearings are known for their accessibility and quick turnaround times. The widespread availability of these bearings from multiple suppliers reduces lead times, minimizing downtime for industries reliant on efficient machinery operation. This accessibility is especially valuable in scenarios where immediate replacements are crucial to prevent disruptions in production.

6. Support and Technical Expertise

Established aftermarket bearing manufacturers prioritize customer support and technical expertise. These companies often provide comprehensive technical assistance, including product recommendations, installation guidance, and troubleshooting support. This commitment to customer satisfaction fosters long-term relationships and instills confidence in the reliability of aftermarket bearings.

Also Read: The Crucial Role Bearing Suppliers Play in India's Industrial Sector

Considerations When Choosing Aftermarket Bearings

While aftermarket bearings offer a range of advantages, it's essential to approach the selection process with due diligence. Consider the following factors to ensure you choose aftermarket bearings that align with your specific needs:

1. Reputation and Track Record

Opt for aftermarket bearing manufacturers with a proven reputation and a track record of delivering reliable products. Customer reviews, industry certifications, and the manufacturer's history can provide valuable insights into their reliability and commitment to quality.

2. Testing and Certification

Make sure the aftermarket bearings you are considering have been thoroughly tested and have the relevant certifications. Certifications, such as ISO standards, indicate that the manufacturer adheres to international quality benchmarks.

3. Customization Options

Evaluate the manufacturer's ability to customize bearings for specific applications. A manufacturer that offers a range of options and customization capabilities is better equipped to meet the diverse needs of different industries.

4. Technical Support

Take into account the extent of technical assistance offered by the producer. A company that offers comprehensive technical assistance can be invaluable in ensuring the proper selection, installation, and maintenance of aftermarket bearings.

The Future of Aftermarket Bearings

As technology continues to advance, the future of aftermarket bearings looks promising. The integration of smart technologies, such as sensors for real-time monitoring, is becoming a focus for some aftermarket bearing manufacturers. This evolution aligns with the broader industry trend toward predictive maintenance, enabling businesses to anticipate and address potential issues before they escalate.

Additionally, advancements in materials, lubrication technologies, and manufacturing processes are likely to further enhance the performance and longevity of aftermarket bearings. As these innovations continue to unfold, aftermarket bearings will solidify their position as a top choice for industries seeking reliable, cost-effective, and technologically advanced solutions.

Wrapping Up

Trusting superior aftermarket bearing manufacturers is a strategic decision that offers numerous benefits to industries relying on efficient and reliable machinery. The evolution of aftermarket bearings has dispelled the notion that they are generic or subpar alternatives to OEM components. Instead, they stand as a testament to innovation, cost-effectiveness, and adaptability to diverse industrial needs.