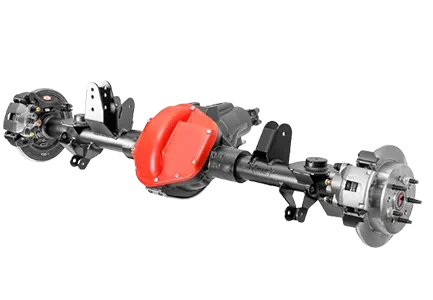

Axle bearings are essential to industrial engineering because they guarantee the efficiency and seamless functioning of machinery in a variety of industries. These parts allow for the transfer of weights and smooth rotational motion, and they are the foundation of many applications, ranging from heavy machinery to automobiles. Leading axle bearings manufacturers' unwavering quest for innovation has revolutionized entire sectors and changed the functioning of these crucial parts, bringing in a new era of improved performance, sustainability, and durability.

The Development of Axle Bearings

Throughout history, axle bearings have been essential components of industry and automotive systems. Their main purpose is to support and facilitate the smooth rotation of axles or shafts, which lowers wear and friction. When traditional bearings were first built, they were made of materials like bronze, which was functional but had drawbacks in terms of longevity, load-carrying capability, and operational lifespan.

Creative Remedies Driving Industry Advancements

The axle bearing manufacturing industry's search for novel solutions has resulted in the creation of cutting-edge technologies and ground-breaking designs. These developments not only tackle current issues but also open the door to increased sustainability, lower maintenance costs, and increased operational efficiency.

Innovative Approaches of Axle Bearing Manufacturers

Innovations in Material Science

The creation of cutting-edge materials is one of the main areas where axle bearings manufacturers are making important advancements. Temperature swings, corrosion, and general wear and tear were common problems for traditional bearings. Leading producers are increasingly using high-performance materials like ceramic composites and sophisticated alloys.

For example, ceramic bearings are renowned for their remarkable longevity, rust resistance, and less friction. Because there are fewer frictional losses, this not only extends the axle bearings' total lifespan but also improves fuel efficiency.

Smart Bearing technology

In the automotive industry, the incorporation of smart technology into axle bearings is a new development. Sensors and monitoring systems that enable real-time data collection on a variety of performance metrics are built into smart bearings. After that, this data is examined to identify possible problems, allowing for proactive maintenance and lowering the possibility of unplanned breakdowns.

To provide axle bearings with integrated sensors that track variables like temperature, vibration, and load conditions, top axle bearing manufacturers are devoting resources to research and development. The car's central control system can receive real-time data produced by these smart bearings, which can provide practical information for predictive maintenance and performance optimization.

Also Read: Technological Advancements Driven by Indian Bearing Companies

Innovations in Seal and Lubrication

Robust sealing and lubrication systems are critical to axle bearing longevity and performance. Manufacturers are responding to the need for bearings that can endure severe operating conditions by launching cutting-edge lubrication methods and creative seal designs. These days, seals are made to be more resistant to impurities like water, dirt, and debris. It guarantees consistent performance even in demanding settings and increases the axle bearings' lifespan. Additionally, improvements in heat dissipation, less friction, and increased overall efficiency are facilitated by breakthroughs in lubrication technologies, such as the use of high-performance synthetic lubricants and greases.

Weight Reduction Strategies

Axle bearing manufacturers are concentrating on creating lightweight alternatives without sacrificing strength and durability in the quest for fuel efficiency and lower carbon emissions. Lightweight materials are included in bearing designs, such as high-strength metals and composite materials, to strike a compromise between weight reduction and structural integrity. Axle bearing weight reduction helps the vehicle's overall weight reduction, which improves handling and fuel economy. It is especially important when it comes to electric vehicles because every kilogram saved corresponds to a longer battery life.

Environmental Sustainability

Leading axle bearing manufacturers are constantly looking for ecologically friendly solutions as the automobile industry places greater emphasis on sustainability. It includes end-of-life concerns and production procedures in addition to the materials utilized in manufacturing. By repurposing materials from outdated bearings, some businesses are investigating the use of recycled materials in bearing production, thereby supporting the circular economy. The environmental effect of axle bearing production is also being reduced through the use of energy-efficient manufacturing techniques and waste-reduction programs.

Difficulties and Opportunities for the Future

Notwithstanding the impressive advancements in axle bearing technology, there are still obstacles to overcome. Researchers and developers in the field are still driven by the desire for even more robustness, increased load capacities, and less maintenance needs.

Furthermore, the need for smart bearings with improved sensing capabilities and predictive maintenance features is anticipated to skyrocket as industries adopt automation and IoT integration. Moreover, adopting sustainable practices continues to be a top concern. Manufacturers are looking for eco-friendly materials and energy-efficient manufacturing techniques to further lessen the environmental impact of bearing production.

Wrapping Up

Leading manufacturers are constantly pushing the boundaries of innovation, transforming the axle bearing industry. The future of axle bearing design is being shaped by the use of cutting-edge materials, clever technologies, improved sealing and lubrication techniques, weight reduction plans, and a dedication to environmental sustainability. Axle bearing producers are essential to improving the efficiency, dependability, and performance of automobiles as the automotive sector develops.

The advancements covered in this article pave the way for a new era of high-performance, intelligent, sustainable axle bearing solutions while also addressing pressing issues. Leading axle bearing producers are expected to have a significant role in influencing the direction of automotive technology as consumers expect better efficiency and dependability from their vehicles.